Years Experiences Of Construction Company

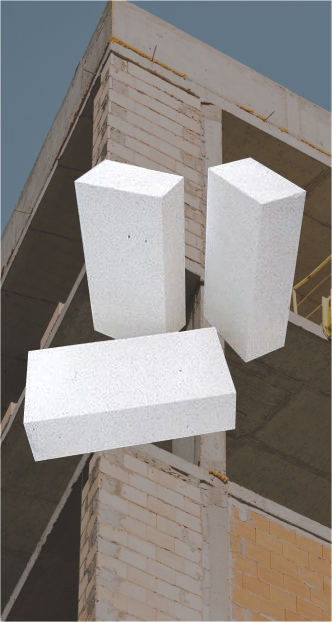

AAC (Autoclaved Aerated Concrete) blocks are lightweight, precast, and eco-friendly building materials widely used in construction projects around the world. Made from natural raw materials such as sand, cement, lime, and aluminum powder, AAC blocks undergo a unique autoclaving process that creates a matrix of tiny air pockets within the material, giving it its characteristic lightweight and porous structure. This process also enhances the thermal insulation properties of AAC blocks, making them ideal for both residential and commercial buildings. Additionally, AAC blocks offer excellent sound insulation, fire resistance, and are easy to handle and install, making them a preferred choice for modern construction projects focused on sustainability, efficiency, and durability.

AAC Blocks are Not heavy in weight, dry and set quickly, better than conventional clay bricks and use for faster option for construction. As a result, the project will be finished on time for builders and their associates.

AAC Blocks reduce wastage with increased utilisation with minor breakage and drastically.

AAC blocks are cost saving for all projects. Being about 66% lighter than conventional clay bricks, it has the following assured savings

1. 25% reduction in foundation load | 2. 10% reduction in cement usage | 3. 15% reduction in steel usage | 4. 35% reduction in the cost of plastering

AAC Blocks has one of the highest hourly fire-resistant ratings per inch of any building material. It will not burn. It has excellent thermal and acoustic insulation which makes it best suited for Air conditioned and fire rated buildings.

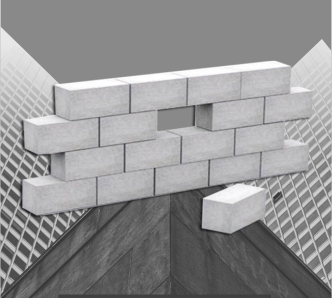

AAC Blocks achieve higher wall strength in thinner walls than conventional bricks achieve in thick walls. This results in increase of the salable and usable carpet area on every floor.

AAC Block comes in pre-defined sizes and constant dimensions which minimizes the time of adjusting them according to the user's requirement.

The impact of earthquake forced on a structure is proportional to the weight of the structure. Hence, Magna AAC Blocks provides excellent resistance to earthquake forces.

AAC Blocks are made up of inorganic materials, which does not get disintergrated, it is not susceptible to external influences and keeps termites away avoiding damages and losses.

| Property | Unit | Unit |

|---|---|---|

| Face Size | mm | 600 x 200 |

| Thickness | mm | 75 | 100 | 125 | 150 | 200 | 230 |

| Dry Weight | kg | 5.25 | 7 | 8.75 | 10.5 | 14 | 16.10 |

| Compressive Strength(min) | N/mm2 | 3 |

| Normal Dry Density | Kg/m3 | 551-600 |

| Thermal Conductivity | W/m-k | 0.15 |

| Sound Reduction | db | 37-42 |

| Fire Resistance-load Bearing (200mm Thickness) | Hrs | 4 |

| Non Load Bearing (100mm thickness) | Hrs | 4 |